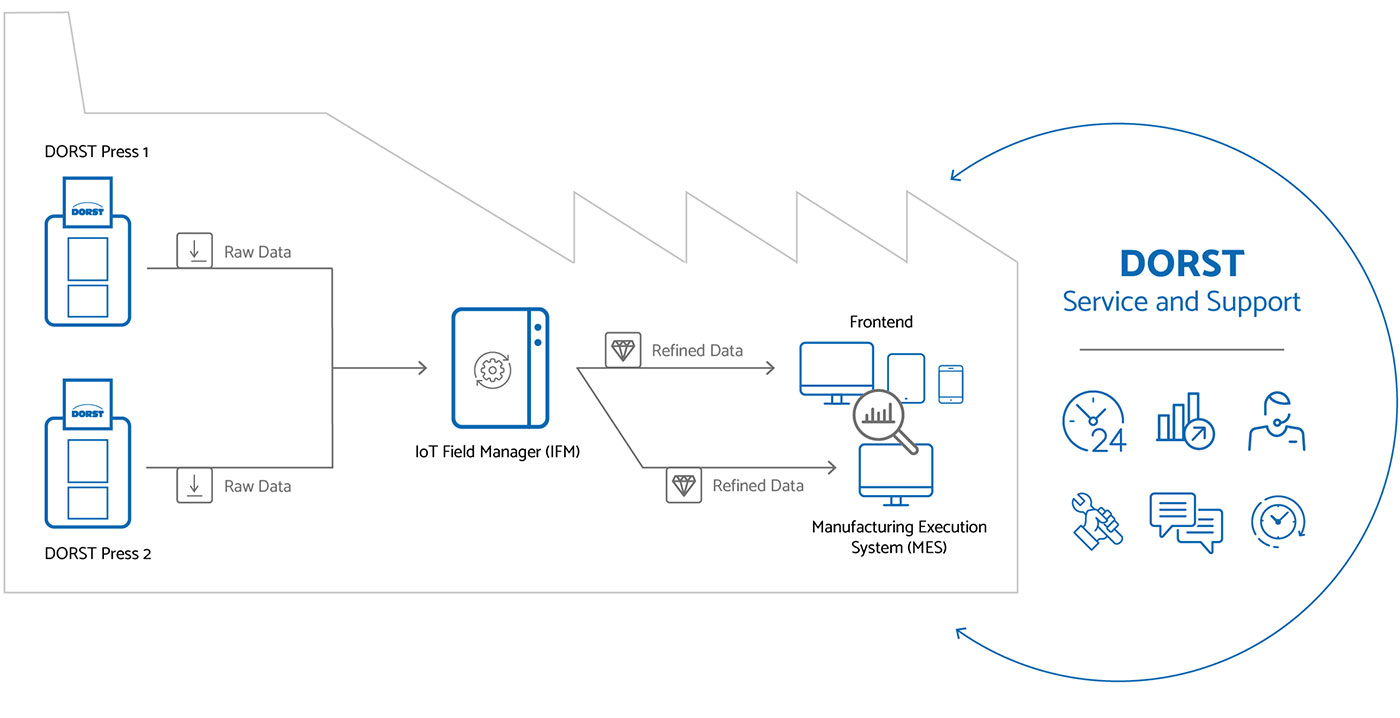

The IoT Package III raises communication between operator and manufacturer of the machine to an entirely new level. This joint view from two different angles opens up a new perception of the machine's condition, possible signs of wear and necessary maintenance measures.

The operator can draw on the manufacturer's expert knowledge so that a planned action based on collected data can replace reaction in the sense of predictive maintenance and service.

Many of DORST TECHNOLOGIES' machines and systems have already been equipped with sufficient sensors for digital data mining. Still, additional sensor packages, depending on the individual machine type, are available for an even more detailed insight into the process and the machine's condition through the IoT Field Manager. To prevent data acquisition from straining the control system of a connected machine, standalone data servers will be installed.